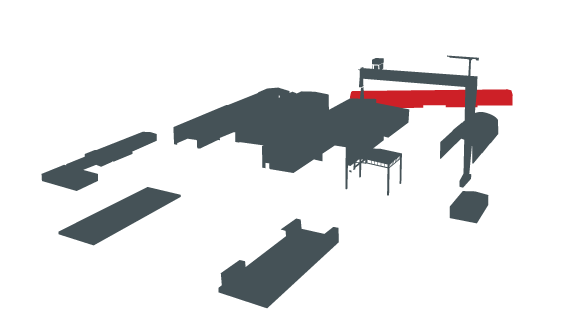

Key Features

- Computer controlled plasma cutting machine

- Computer controlled robotic profile line

- Oxy fuel cutting machine

- Five (5) bridge cranes (5T to 20T)

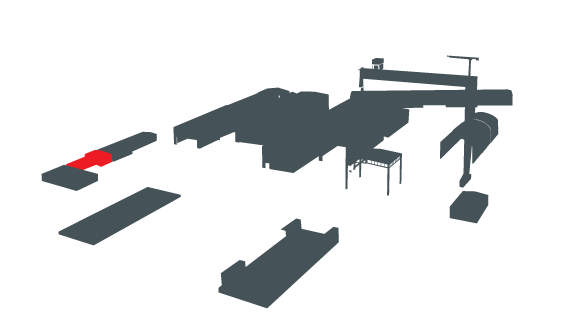

Dimensions

- 168m long x 24m wide

(551 ft. x 78 ft. wide) - Total size: 4000m²

(43,000 sq. ft.)

Workforce

- 30 to 40 employees per shift

- The facility operates 16 hours/day, 5 days a week

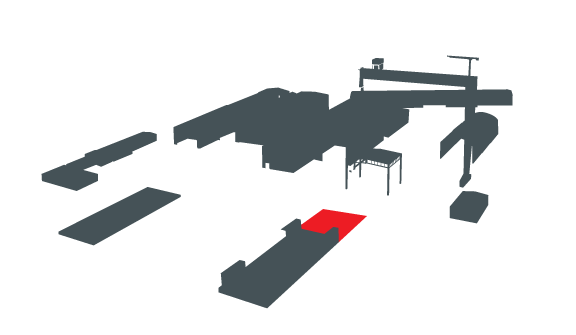

Description

The Sub Assembly Shop is the first stop in the shipbuilding process. Steel is delivered to this facility, which houses the most world-class, state-of-the-art equipment available for shaping and cutting flat steel.

In addition to a 13 meter ESAB plasma cutting/tracing/beveling/marking machine, which covers two work stations to provide for a continuous flow of work (steel can be loaded and cut on one while another is prepped), the 4000m² (43,000 sq. ft.) shop also includes a processing line for fabrication of parts from shapes, a line equipped with a CNC robotic cutting machine, and five (5) stations dedicated to the assembly of small parts and sub-assemblies.

Before leaving the Sub Assembly Shop, steel is assembled with accompanying pieces into a pre-set "kit" before moving into the next stage of construction.

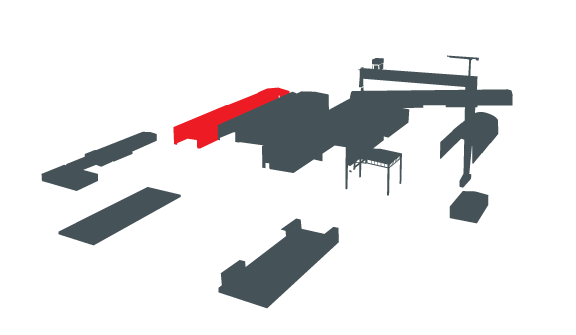

Key Features

- Panel Line (automated conveyor line to produce 12m x 12m

(39 ft. x 39 ft.) flat stiffened panels) - Single-side plate welding

- Panel cutting, layout and marking

- Stiffener fitting

- Stiffener welding

- Three manual stations for installation of web frames, bulkheads, etc.

Dimensions

- 170m long x 28m wide

(557 ft. long x 91 ft. wide) - Total size: 4760m²

(51,236 sq. ft.)

Workforce

- 30 to 40 employees

- The shop operates 16 hours/day,

5 days/week

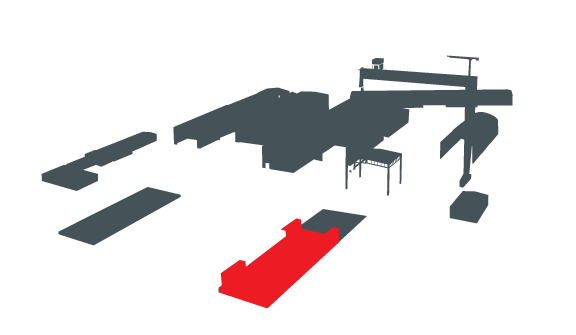

Description

Efficiency is the operative word for this step in the shipbuilding process. The purpose of the Panel Shop is to produce flat panels. To start the procedure, a three-headed submerged arc Welding Machine from Lincoln Electric joins steel plates up to 12m (39 ft.) in length. The unit welds two plates together on one side and in one pass, making the process approximately 14 times quicker than the old method, which also required more manpower for tasks like turning the gigantic panels.

In addition, the PEMA Panel Line is 100% accurate for cutting the perimeter of the panel and all the holes required for installation of piping, cabling, etc. Following the steel down the conveyer belt, angle bars are fastened (again, with greater efficiency and accuracy) as six (6) automated welding heads working at once provide amazing efficiencies for the joining of stiffeners to the line panel.

By the time the panel reaches the end of the line, it's ready to be moved using self propelled modular transporters (SPMTs) to the next shop.

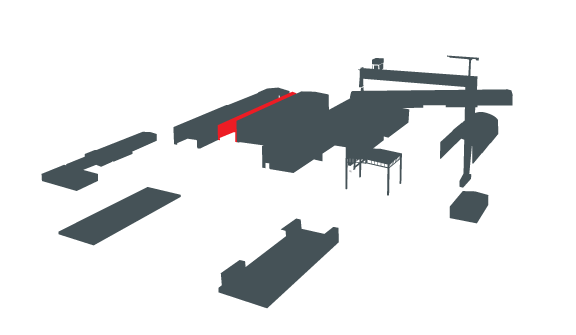

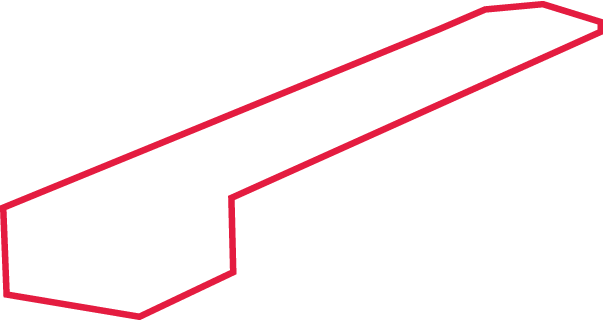

Key Features

- 1000T plate press

- 1000T press brake

- 400T press brake

- 400T stiffener forming

- 8ft. plate rolls

Dimensions

- 130m long x 14m wide

(426 ft, long x 45 ft. wide) - Total size: 4160m²

(51,218 sq. ft.)

Workforce

- 10 to 15 employees

- The shop operates 16 hours/day,

5 days/week

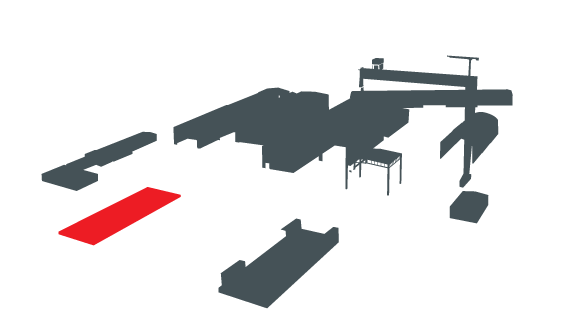

Description

The Forming Shop forms/bends steel plates and profiles to the ship's final hull shape. This shop also boasts one of the most technologically advanced pieces of machinery in shipbuilding today - the Nieland Hydraulic Plate Press. The Nieland is a cold forming press that can shape steel up to two and a half inches thick. Once the steel is formed, it moves to a section within the Block Assembly Shop that consists of steel "pins" to allow pieces to be welded together.

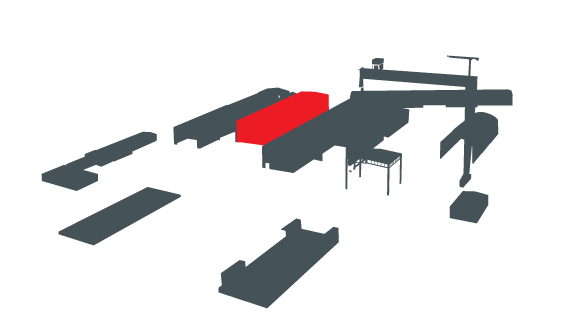

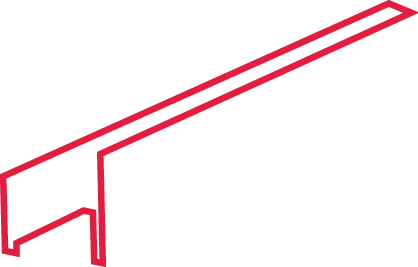

Key Features

- Two 40T overhead cranes, each with two 40T trolleys

- Two 15T overhead cranes used for setting of web frames, bulkheads, etc.

- Pin jigs (adjustable telescoping pipes) for supporting curved panels during their manufacturing process

Dimensions

- 130m long x 30m wide

(426 ft. long x 98 ft. wide) - Total size: 3900m²

(42,000 sq. ft.)

Workforce

- 100 to 120 employees per shift

- The shop operates 16 hours/day,

5 days/week

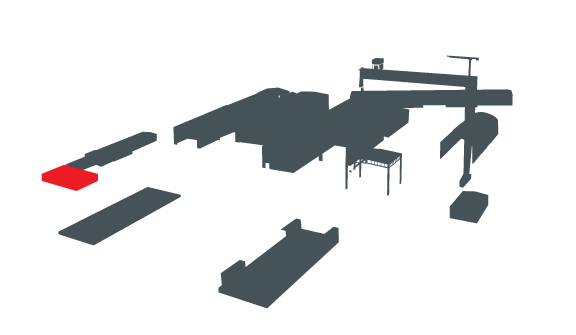

Description

This is a new state of the art facility for fitting and welding of vessel hull blocks up to 24m x 24m (78 ft. x 78 ft.) in size. The Block Assembly Shop is also where curved and three-dimensional blocks are manufactured along with installation of hot outfitting items, like hangers for cables and pipes. With the fastening of welded sub-assemblies and panels together, the vessel starts to take a recognizable shape in this shop. The steel panels from the panel line and the sub-assemblies are welded, formed and brought together in 20 to 40 tonne pieces and are assembled in this shop before taking one of two routes, either directly to the Pre-Outfit Shop or more typically to the Blast & Paint Shop.

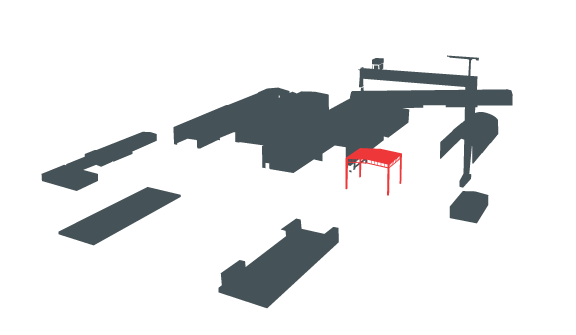

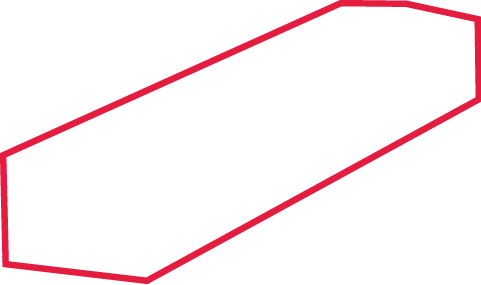

Key Features

- Block Outfitting (five bays to install equipment, pipe, ventilation and electrical systems with overhead cranes)

- Module Construction (two bays for installation of outfit components onto structural frameworks)

Dimensions

- 180m long x 29m wide

(590 ft, long x 95 ft. wide) - Total size: 5220m²

(56,150 sq. ft.)

Workforce

- 100 to 120 employees in the Pre-Outfit Shop

- 100 to 150 employees in the Operations Centre (office)

- This shop operates 16 hours/day,

5 days/week

Description

This is a new dual purpose, two-floor facility. The first floor consists of warehousing facilities and two (2) bays for the fabrication and assembly of equipment modules plus five (5) bays for the outfitting of vessel hull blocks with mechanical, piping, cables, HVAC, electrical and any other system requirements.

While the second floor houses Vancouver Shipyard's Operations Centre with offices, conference rooms, training rooms, a 600-seat lunchroom and other trade amenities.

Key Features

- Two blast positions

- Steel grit vacuum and elevator recovery system

- Dedicated dust collection systems

- Four paint positions

Dimensions

- 60m long x 46m wide

(196 ft. long x 150 ft. wide) - Total size: 2760m²

(30,000 sq. ft.)

Workforce

- 25 to 50 Employees

- The shop operates 16 hours/day,

5 days/week

Description

The New Construction Blast & Paint Shop is used for grit blasting, surface preparation (i.e. the removal of rust and contaminants), and the painting of hull blocks, while the Repair Blast & Paint Shop was an existing facility modernized to include new cladding, ventilation and blasting equipment and a new sliding door at the south end, similar in design to an aircraft hanger. Both shops adhere to the highest environmental standards (they are fully ventilated and have filtration systems that capture particulate matter and other debris).

Key Features

- Upgraded from previous fabric-walled building that had natural ventilation

- Shop used for third party ship repairs, as well as Seaspan's fleet of tugs and barges

- Can accommodate vessels up to 75m (246 ft.) in length and 22m

(72 ft.) in height

Dimensions

- 76m long x 26.2m wide

(249 ft. long x 85 ft. wide) - Total size: 2000m²

(21,500 sq. ft.)

Workforce

- 15 to 25 employees

- The shop operates 16 hours/day,

5 days/week

Description

The New Construction Blast & Paint Shop is used for grit blasting, surface preparation (i.e. the removal of rust and contaminants), and the painting of hull blocks, while the Repair Blast & Paint Shop was an existing facility modernized to include new cladding, ventilation and blasting equipment and a new sliding door at the south end, similar in design to an aircraft hanger. Both shops adhere to the highest environmental standards (they are fully ventilated and have filtration systems that capture particulate matter and other debris).

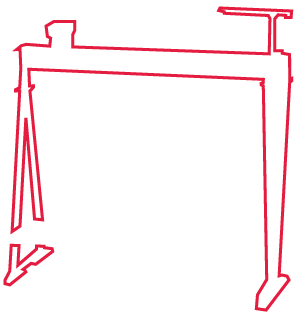

KEY FEATURES

- Hook height – 70m (220 ft.)

- Bridge span – 76m (249 ft.)

- Travel speed – 30m (98 ft.)

per minute - Hoist speed – 12m (39 ft.)

per minute

Dimensions

- 80m high x 76m wide

(262 ft. high x 249 ft. wide)

Workforce

- One crane operator with a 4 to 6 member ground crew

- The crane operates 16 hours/day, 5 days/week

Description

Canada's largest permanent gantry crane, with a lifting capacity of up to 300 tonnes, is used for the pre-erection and erection of blocks and grand blocks (pieces of the ship welded together to form the final product). The crane sits on rails that travel 250 metres (820 ft.) north and south.

In May 2014, following hundreds of student submissions, Seaspan officially revealed the name of its newly assembled crane. Announcing the crane's new name - Hiyí Skwáyel, the Squamish language translation of "Big Blue" (pronounced hee-yay sk-why-el) – was the final step in an extensive evaluation process that began with a multi-week "Crane Naming Contest" with North Vancouver School District students. The contest, which called on more than 4400 students in Grades 4-7 from 25 schools across North Vancouver to come up with their best proposed name in two words or less, produced an overwhelming response, with 228 original submissions, including the winning entry from Boundary Elementary's Ella Tinto.

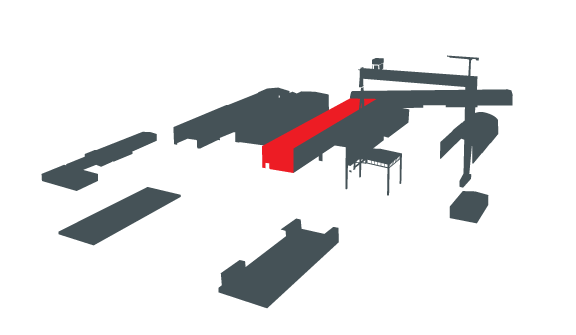

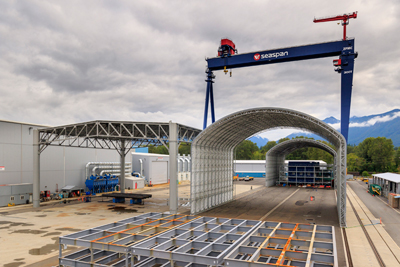

Description

The pre-erection area, located on the east side of the yard and under the 300T gantry crane, is used to join and outfit blocks together to form grand blocks

Rolling shelters are transferred over the blocks/grand blocks to provide sheltered workplaces. Once the grand blocks are complete and assembled as one large section, the shelters are moved and the 300T gantry crane lifts the grand blocks (if not exceeding 300T) onto the erection berth. For grand blocks forming the bottom of the vessel, these can reach up to 800T and are moved by self propelled mobile transporters (SPMTs) to the erection berth.

The final assembly area (erection berth) receives all grand blocks for the final assembly of the vessel including the completion of all outfitting, testing of systems, and final paint and touch ups. The vessel must be completed to 95% before leaving the berth for its first trip to the water.

Description

The transfer of the vessel from land to sea consists of a roll-on floating platform, which is then transferred into deeper water and sunk, leaving the new vessel to float.

The floating platform is called the Seaspan Careen, an autonomous drydock with its own generators to provide power. The Loadout Pier was constructed at the end of the erection berth in order to tie the drydock into the yard and with sufficient water depth. The end of the Loadout Pier measures 32m (104 ft.) in width, the same as the Seaspan Careen.

Description

The Seaspan Careen is an autonomous drydock (self contained, self powered).

It measures 131m (429 ft.) long and the distance between the top deck towers is 33.5m (109 ft.). The lifting capacity of the drydock is 30,000 DWT.

Description

The SyncroLift is a fully functional ship lift measuring 82m long x 21m wide (270 ft. long x 70 ft. wide).

It has a lifting capacity 1150 tons and 259m (850 ft.) of water berth.

Key Features

- Total size: 1742m² (18,750 sq. ft.)

- 2 lathes

- Up to 8.6m (28 ft.)

- 1 horizontal milling machine

- 2 vertical milling machines

Milling Machines

- Maintenance

- Pipefitting

- Mechanical

- Electrical

- Joiner

- Machine Shop

Description

The Machine Shop is composed of various milling machines (both horizontal and vertical), plus small and medium lathes up to 8.6m (28 ft.) in length, press drills, a band saw, and other small equipment.

The typical machining is job shop type of work. It is single piece on short batch, and the machinery available is in relation to this non-continuous process.

Key Features

- Towline installation, repairs and maintenance

- All types of wire cable installations

- Hand splicing and socketing

- Lifting device testing

- On board ship testing of davits, slings, cables, etc.

Description

The Machine Shop is composed of various milling machines (both horizontal and vertical), plus small and medium lathes up to 8.6m in length, press drills, a band saw, and other small equipment.

The typical machining is job shop type of work. It is single piece on short batch, and the machinery available is in relation to this non-continuous process.